Too Much Noise, Too Little Flying

Above bustling city streets, delivery drones and eVTOL air taxis now carve invisible corridors through the sky yet for many residents, their distinctive whine is neither futuristic nor welcome. Laboratory and field studies show that typical open-rotor electric motors emit sharp, high-frequency tones that carry further in urban canyons, triggering complaints and stress responses akin to those first documented by the EPA in the late 1970s. Even when marketed as “quieter than helicopters,” many systems still exceed local noise thresholds, prompting city councils to pause pilot programs and redraw flight paths at community hearings.

Beneath the din lies a more fundamental constraint: energy density. Jet A fuel boasts roughly 12,000 Wh/kg, whereas state-of-the-art lithium-ion battery packs deliver barely 200–300 Wh/kg. This disparity forces designers to trade off range and payload against the added weight of batteries, confining electric platforms to short hops and niche surveillance roles rather than reliable point-to-point transport. While next-generation chemistries like solid-state, lithium-sulfur promise incremental gains, they face rigorous safety, cost, and scaling hurdles before they can match jet-fuel benchmarks.

On top of this, certification adds another layer of complexity. The FAA’s new “powered-lift” rule, finalized in October 2024, outlines a path for eVTOL aircraft, but the multi-stage type-certification process remains lengthy and resource-intensive. Joby Aviation’s recent progress in navigating three of five certification steps over several years highlights both promise and persistent uncertainty. Evolving safety standards, data requirements, and flight-test regimes deter some investors and compel OEMs to stretch out funding rounds, slowing the pace from prototype to revenue-generating fleets.

Finally, the materials at the heart of electric motors remain a strategic vulnerability. Neodymium-iron-boron magnets require rare-earth oxides, over 80 percent of which are processed in China. When Beijing expanded export controls in 2023, curbing not only mined minerals but also finished magnet products global manufacturers felt immediate reverberations. Diversification efforts in Australia, the U.S., and recycling can mitigate risk, but developing alternative supply chains and processing capacity is a multi-year, capital-intensive endeavor.

Together, these intertwined barriers – acoustic pollution, low battery energy-density, murky certification pathways, fragile community trust, and geopolitically fraught materials keep electric aviation grounded. Addressing them in silos will never suffice; the next leap requires propulsion systems engineered holistically for silent operation, optimized efficiency, regulatory alignment, transparent impact modeling, and supply-chain resilience. Only then can the vision of truly quiet, clean, and scalable flight take off.

Rethinking Propulsion For The New Era

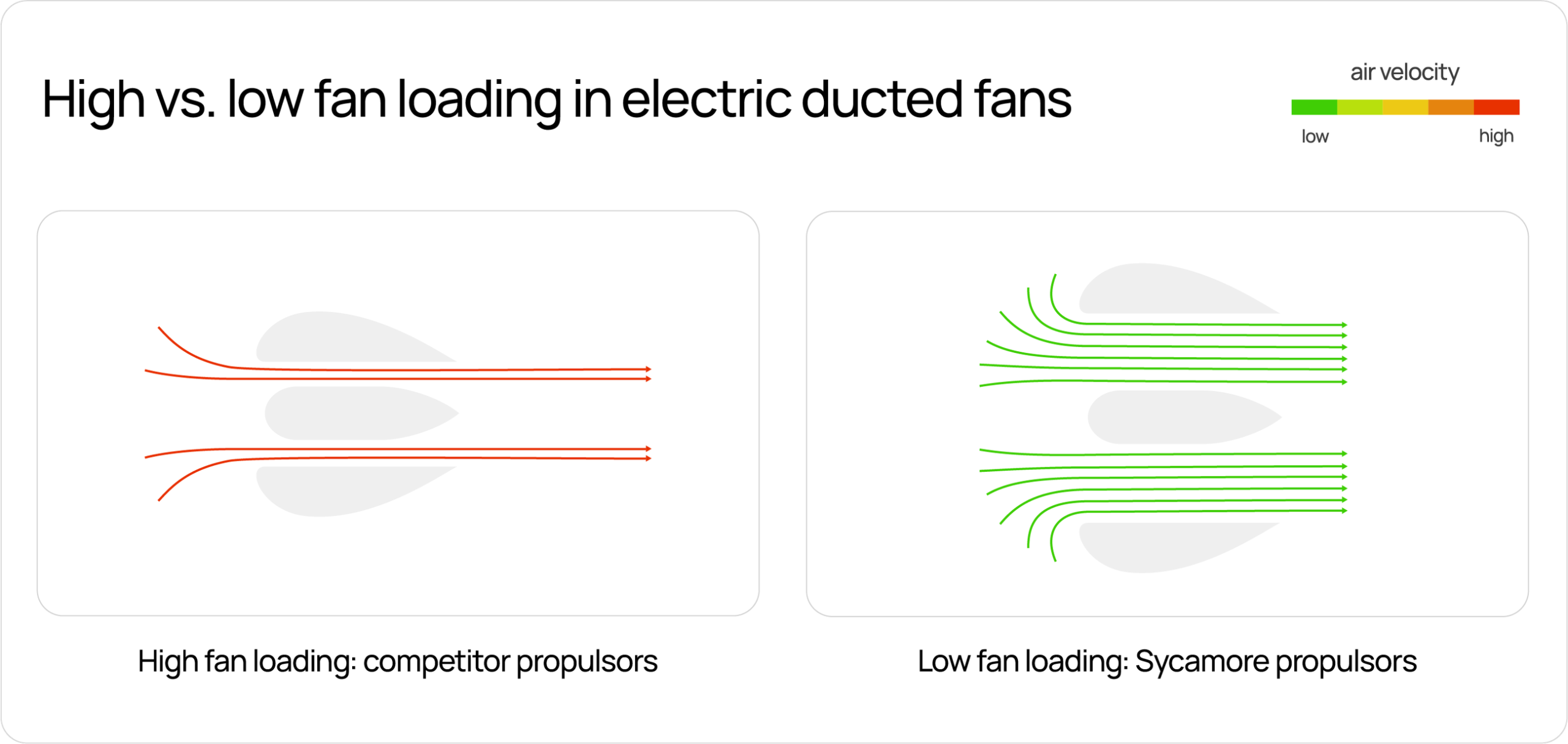

Most electric aviation systems flying today weren’t built for the skies they now occupy. They borrow from hobbyist designs or industrial-grade rotors, resulting in propulsion that is loud, inefficient, and fundamentally ill-suited to life above cities. These open-rotor setups hum with high-frequency noise; piercing enough to disrupt neighborhoods, loud enough to stall community acceptance, and messy enough to make regulators hesitate.

Greenjets took a different path.

From day one, the team chose not to retrofit the past, but to build for the world ahead designing electric ducted-fan systems from the ground up. Their technology doesn’t just look cleaner; it sounds like it. By enclosing rotors and engineering airflow with surgical precision, Greenjets has achieved acoustic signatures up to 10× quieter than open-rotor equivalents without compromising on thrust or control. In urban air mobility, where public trust often hinges on decibels, that difference is more than technical, it’s cultural.

This innovation is more than skin deep. Instead of bolting together off-the-shelf fans and battery packs, Greenjets has reimagined the propulsion module as a tightly integrated system: cooling, structure, and control working together as one unit. That vision became reality in early 2023, when Greenjets unveiled the world’s first electric jet engine demonstrator built specifically for commercial drone platforms. It wasn’t just a breakthrough in performance. It was proof that safety, certification, and silence could be engineered not as trade-offs, but as table stakes. And they couldn’t have timed it better.

As aviation faces unprecedented pressure to decarbonize, battery technology is catching up, short-haul routes are opening up, and regulators are finally aligning behind eVTOL certification frameworks. Cities are laying the groundwork for aerial corridors but grounding noisy operators. In parallel, defense agencies are seeking next-gen drones that are stealthier, more agile, and energy efficient.

Greenjets fits squarely into this moment. Especially as geopolitical fault lines sharpen and rare-earth dependencies become liabilities. In April 2025, China tightened export controls on critical magnet materials, sending a shockwave through global EV and aerospace supply chains. But Greenjets had already made the hard choice: to avoid reliance on Chinese rare-earths altogether, sourcing instead from emerging suppliers in the West and Australia. That decision, once contrarian, now feels prescient.

Behind the product is a team that knows propulsion to its core. CEO Anmol Manohar brings deep experience from Rolls-Royce and Formula 1, blending engineering rigor with high-speed iteration. Dr. Guido, formerly at BAE Systems, leads development with expertise in advanced turbomachinery and simulation. Together, they’ve built a team that moves fast without cutting corners—balancing aerospace-grade safety with startup-grade urgency.

Supporting them is a circle of experienced advisors, including industry veteran Colin Smith, whose leadership in global aviation programs brings the kind of perspective that only decades at the frontier can provide.

The result is a company that doesn’t just build electric engines, it’s rewriting the template for how electric flight should sound, feel, and scale.

The Flight Ahead

Greenjets isn’t just building engines, it’s building belief.

Belief that the sound of flight can fade into the background. That clean, quiet propulsion isn’t a long-term goal but it’s ready for testing, for integration, for the skies.

This isn’t a theory. In March 2024, Greenjets and Ricardo unveiled the InCEPTion demonstrator; a fully integrated, ducted-fan propulsion system built for aircraft under five tonnes. It was a step toward flight that is quiet, scalable, and certifiable.

And the work continues. Through a research partnership with the Whittle Laboratory at Cambridge, Greenjets is combining engineering with climate modeling, exploring not just how to fly quieter and cleaner, but how to prove it scientifically, publicly, and at scale. In parallel, collaborations with edge-focused partners like Firestorm Labs are pushing the platform into the field, testing how modular units can perform in the real world, under real constraints.

This is what momentum looks like.

But perhaps most importantly, Greenjets is doing this without shortcuts with no rare-earth reliance and no supply-chain guesswork. In a world increasingly wary of fragility, the team is building with resilience in mind sourcing consciously, manufacturing locally, and preparing for a future where propulsion isn’t just cleaner, but smarter and more sovereign.

For the industry, the signals are clear: certification frameworks are maturing, battery tech is catching up, and cities are preparing the infrastructure. What’s been missing is propulsion that meets the moment—with the performance, the silence, and the trust to scale.

Greenjets is building exactly that. And they’re not waiting for the future to arrive. They’re flying toward it.